In the world of electronics, where signals travel at lightning speed and devices are expected to operate without interference, one component stands out as a quiet but essential guardian of signal integrity: the common mode choke core. Though it may not be as glamorous as microprocessors or as visible as connectors, the common mode choke core plays a vital role in ensuring that electronic systems function smoothly and efficiently.

At its core (pun intended), a common mode choke is an inductor designed to suppress electromagnetic interference (EMI) in electrical circuits. Its primary purpose is to filter out unwanted noise that can disrupt the performance of sensitive electronics. This noise often appears in the form of "common mode" signals—unwanted electrical currents that flow in the same direction on both conductors of a paired line. Unlike differential mode signals, which are the desired signals traveling in opposite directions, common mode signals are essentially parasitic and need to be eliminated to maintain system stability.

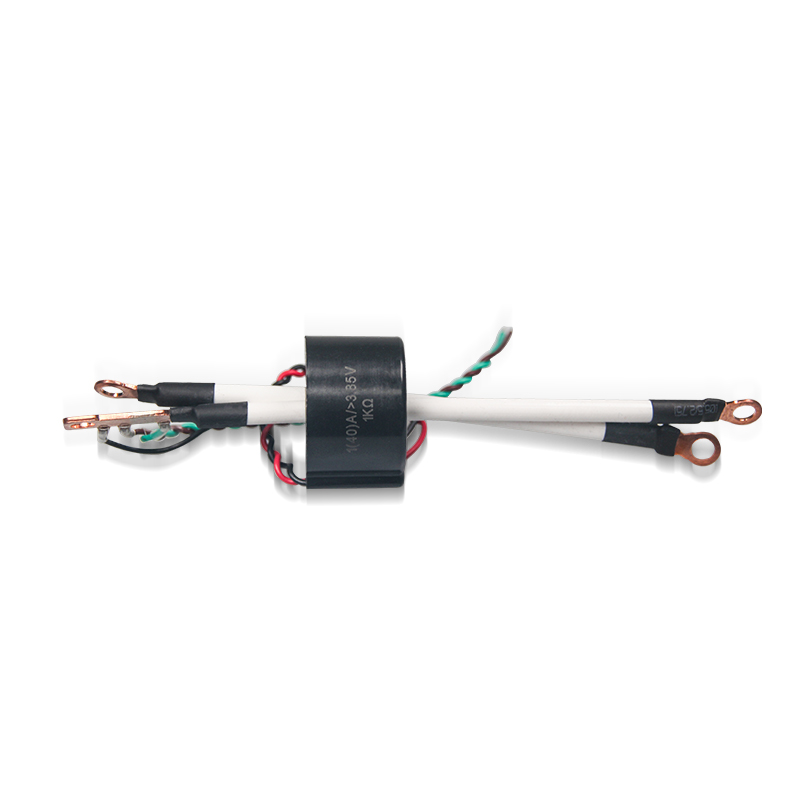

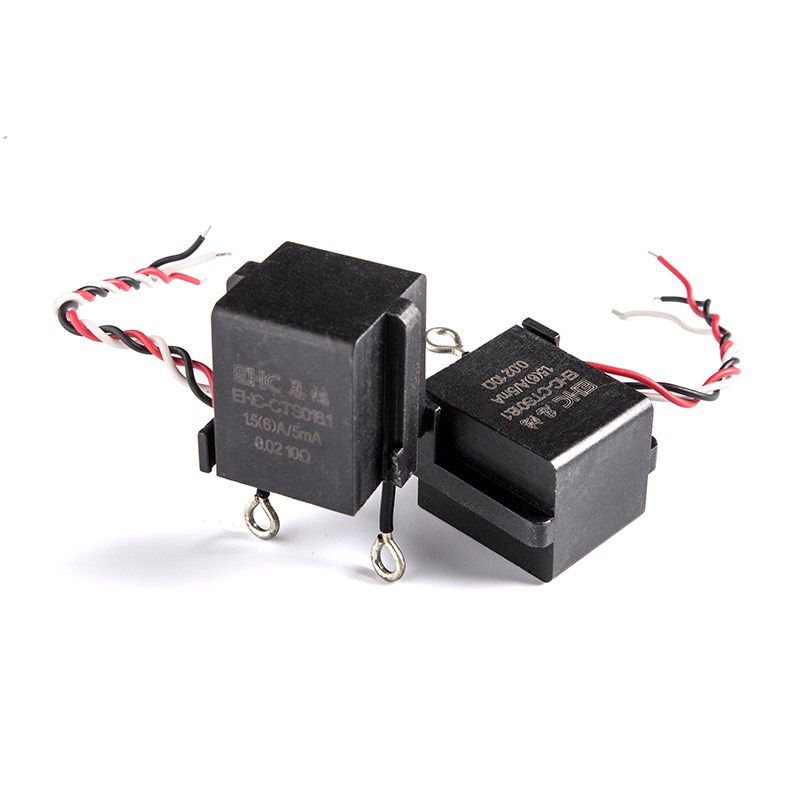

The heart of any common mode choke is its core material. The core is typically made from ferrite, a ceramic-like compound composed of iron oxide mixed with other metals such as manganese, zinc, or nickel. Ferrite cores are prized for their high magnetic permeability and low electrical conductivity, making them ideal for applications where EMI suppression is critical. When wound with insulated copper wire, the ferrite core creates an inductive impedance that blocks high-frequency noise while allowing the desired low-frequency signals to pass through unimpeded.

One of the key advantages of using a common mode choke core is its ability to protect against both radiated and conducted emissions. Radiated emissions are electromagnetic waves that escape into the surrounding environment, potentially interfering with nearby devices. Conducted emissions, on the other hand, are noise signals that travel along wires and cables, infiltrating connected systems. By placing a common mode choke in series with these pathways, engineers can effectively "choke off" the unwanted noise, preventing it from propagating further.

Common mode chokes are ubiquitous in modern electronics, finding applications in everything from power supplies and data lines to audio equipment and telecommunications devices. For example, in switch-mode power supplies, they help reduce the high-frequency noise generated by fast-switching transistors. In USB cables and HDMI interfaces, they ensure that high-speed data transmission remains free from interference. Even in automotive electronics, where harsh environments and stringent regulations demand robust EMI solutions, common mode choke cores are indispensable.

Selecting the right core material and design for a specific application requires careful consideration. Factors such as frequency range, current handling capacity, and temperature stability all influence the choice of core. For instance, nickel-zinc ferrites are often preferred for high-frequency applications due to their excellent attenuation properties, while manganese-zinc ferrites are better suited for lower frequencies where higher permeability is needed.

Despite their small size and relatively simple construction, common mode choke cores have a profound impact on the reliability and performance of electronic systems. Without them, the delicate balance between functionality and interference would tip precariously, leading to degraded performance, data corruption, or even complete system failure. As technology continues to advance, with faster processors, denser circuit boards, and more interconnected devices, the importance of effective EMI suppression will only grow.

और देखें >>

और देखें >> और देखें >>

और देखें >> और देखें >>

और देखें >> और देखें >>

और देखें >> और देखें >>

और देखें >> और देखें >>

और देखें >> और देखें >>

और देखें >>